1. Introduction: The Role of Fish Feed in Modern Aquaculture

The global demand for seafood continues to rise, making aquaculture a vital contributor to food security and economic growth. Central to modern fish farming is high-quality feed, and the fish feed pellet making machine plays a critical role in producing consistent, nutrient-rich pellets suitable for various fish species.

Unlike traditional feeding methods, which relied on natural resources like plankton and raw grains, mechanized feed production ensures balanced nutrition, reduces waste, and supports large-scale commercial operations. Farms investing in fish feed pellet making machines can optimize growth rates, enhance fish health, and meet both domestic and international market demands.

2. Historical and Cultural Context of Fish Farming

Fishing has been a primary source of protein for thousands of years, but traditional aquaculture practices relied heavily on natural feed, often inconsistent in quality and availability. As aquaculture shifted from small ponds to industrial operations, it became necessary to produce formulated feed that could meet the nutritional requirements of farmed fish species such as tilapia, catfish, carp, and salmon.

The development of the fish pellet making machine reflects a combination of centuries-old aquaculture knowledge with modern engineering. In countries with a strong aquaculture culture—such as Vietnam, Thailand, Indonesia, and China—pelletized feed has revolutionized farming efficiency, providing farmers with precise feeding solutions while maintaining traditional aquaculture practices.

3. Components and Function of a Fish Feed Pellet Making Machine

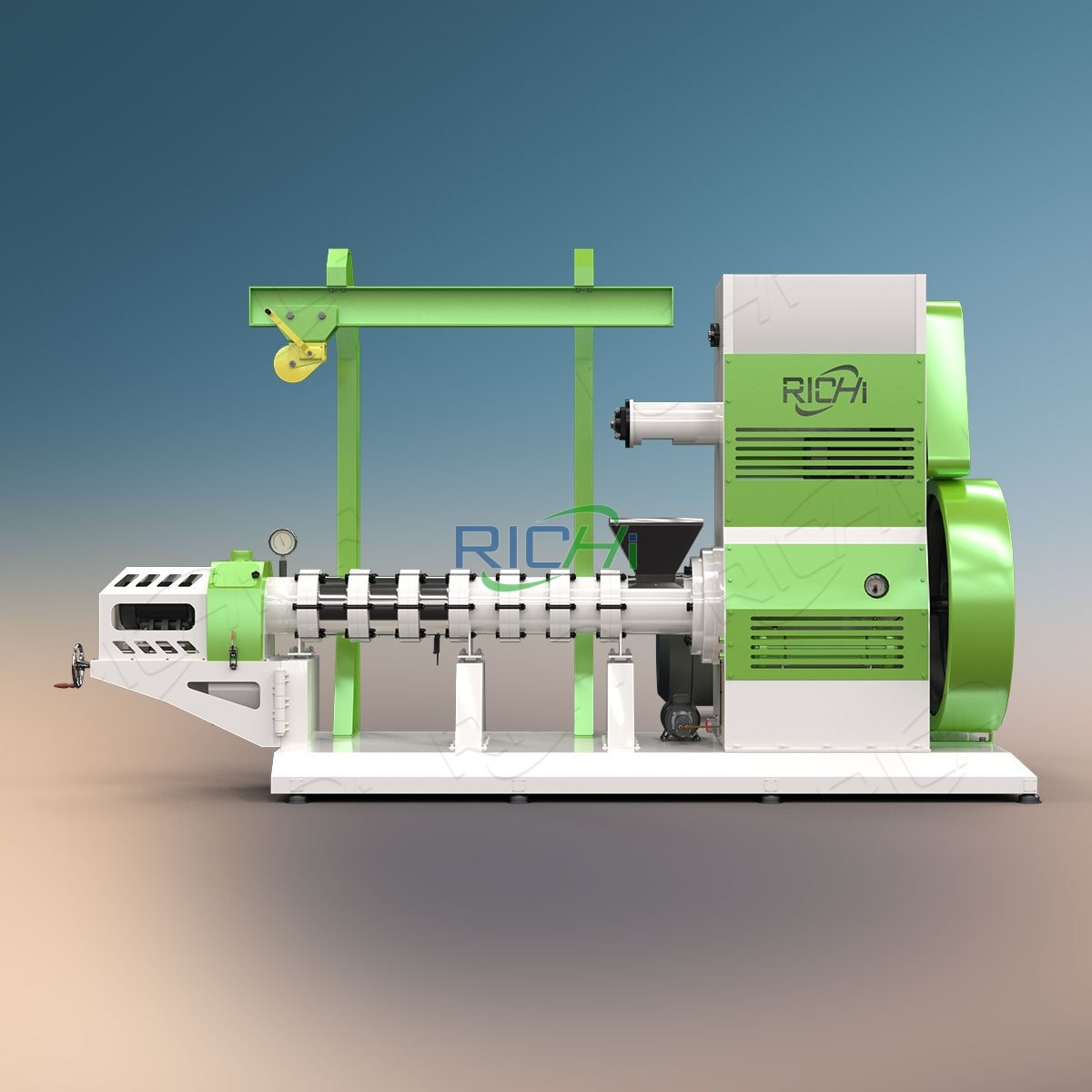

A typical fish feed pellet making machine system consists of several essential components:

Raw Material Grinder: Reduces fish meal, soybean meal, corn, and other ingredients into fine powder for uniform mixing.

Mixer: Ensures even distribution of nutrients, vitamins, and minerals in the feed.

Pellet Mill / Extruder: Compresses the mixed feed into floating or sinking pellets based on fish species and feeding habits.

Dryer: Reduces moisture content to extend shelf life and prevent spoilage.

Cooling System: Maintains pellet integrity, preventing breakage during storage and transport.

Packaging System: Prepares feed for distribution and commercial sale.

Modern machines often include automated controls and adjustable parameters for pellet size, density, and nutrient composition. Reputable suppliers such as RICHI provide modular systems adaptable to both small farms and large industrial operations.

4. Advantages of Using a Fish Feed Pellet Making Machine

Investing in a fish feed pellet making machine offers multiple advantages for aquaculture operations:

Balanced Nutrition: Pellets contain proteins, fats, vitamins, and minerals, ensuring optimal fish growth.

Efficient Feeding: Floating or sinking pellets allow precise feed control, minimizing waste and water pollution.

Consistency: Automation ensures uniform pellet size and nutrient distribution.

Scalability: Machines can be adapted for small-scale farms or large industrial setups.

These benefits lead to improved growth rates, higher survival, and better feed conversion ratios, making pellet production indispensable for commercial fish farming.

5. Technological and Environmental Considerations

Producing high-quality fish feed requires careful control of moisture content, temperature, and pellet density. Excessive moisture can result in disintegrated pellets, while insufficient moisture may increase wear on the pellet machine.

Modern fish feed pellet making machines, including those offered by RICHI, utilize advanced extrusion technology, automated drying systems, and monitoring controls. These features preserve nutrients, maintain pellet durability, and produce feed suitable for floating or sinking preferences of various fish species.

From an environmental perspective, mechanized pellet production reduces feed waste and water pollution. Efficient pellet production also allows the use of agricultural by-products, such as rice bran or corn gluten, promoting circular economy practices in aquaculture. https://richipelletizer.com/fish-feed-milling-machine/

6. Economic and Market Significance

Feed costs account for 40–60% of total aquaculture expenses, making efficient production of high-quality feed critical to farm profitability. Investing in a fish feed pellet making machine enables farms to produce feed on-site, reducing dependency on external suppliers and lowering overall costs.

The global fish feed market continues to expand, driven by rising seafood consumption in North America, Europe, and Asia. Mechanized feed production allows farms to meet domestic and export market standards, creating economic opportunities while ensuring sustainable growth.

7. Choosing the Right Fish Feed Pellet Making Machine

Selecting an appropriate fish feed pellet making machine involves considering several factors:

Capacity: Machines range from small-scale 0.5–2 tons per hour units to industrial-scale 5–20 tons per hour systems.

Feed Type: Floating or sinking pellets tailored to specific fish species.

Automation Level: Advanced control systems reduce labor, maintain consistency, and optimize production efficiency.

Supplier Reliability: Working with trusted manufacturers such as RICHI Machinery ensures technical support, spare parts, and long-term service.

Proper machine selection maximizes efficiency, reduces operational risk, and ensures high-quality pellet production for commercial and industrial aquaculture. More Info

8. Cultural and Nutritional Importance of Fish Feed

Fish is a critical source of protein and essential fatty acids in many cultures. A fish feed pellet making machine ensures that farmed fish grow efficiently, remain disease-resistant, and provide consistent nutrition for human consumption.

In addition to nutritional benefits, pelletized feed contributes to cultural and economic sustainability by supporting local fisheries, creating jobs, and enabling communities to adopt modern aquaculture practices without compromising traditional methods.

9. Conclusion: Investing in Sustainable Fish Farming

A fish feed pellet making machine represents a strategic investment in modern aquaculture. It provides consistent, nutrient-rich feed that enhances fish growth, reduces environmental impact, and supports profitability.With reliable solutions from suppliers like RICHI, farms can scale production, meet market demand, and maintain sustainability. As global seafood consumption rises, mechanized feed production remains central to efficient, responsible, and profitable aquaculture practices. Floating Fish Feed Production Line In Russia